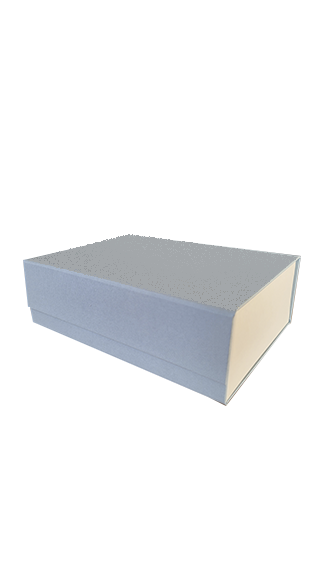

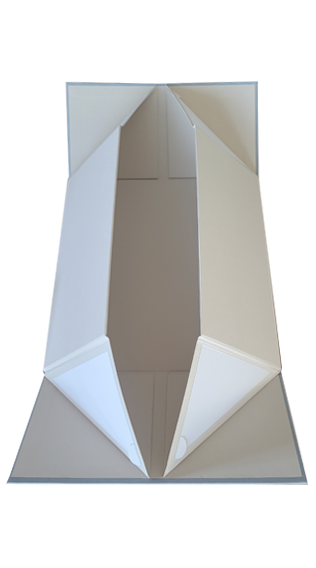

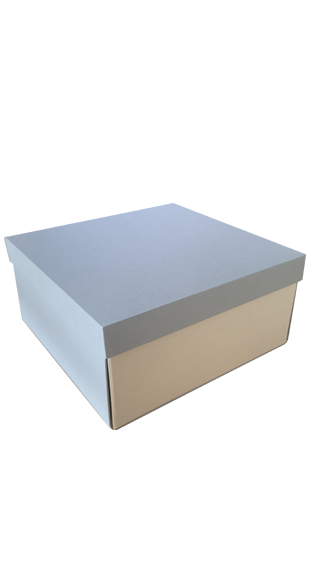

COLLAPSIBLE RIGID GIFT BOX

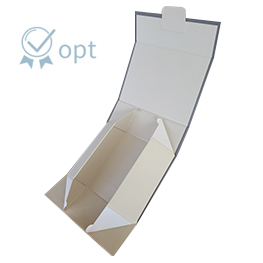

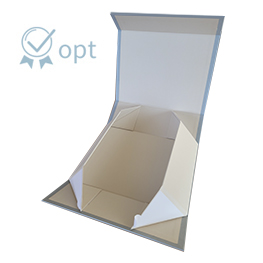

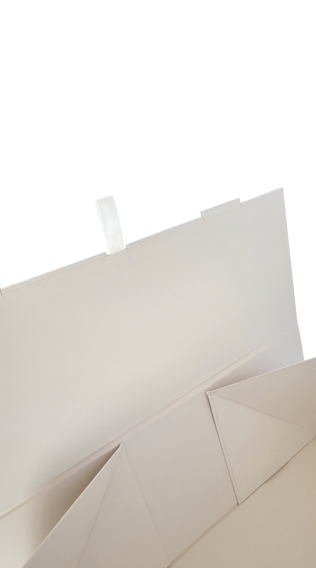

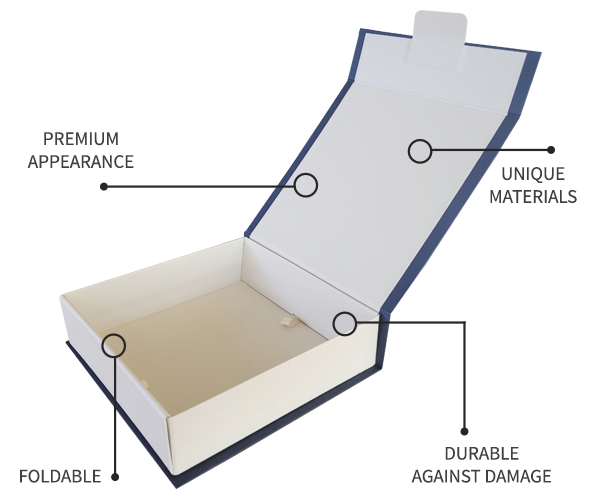

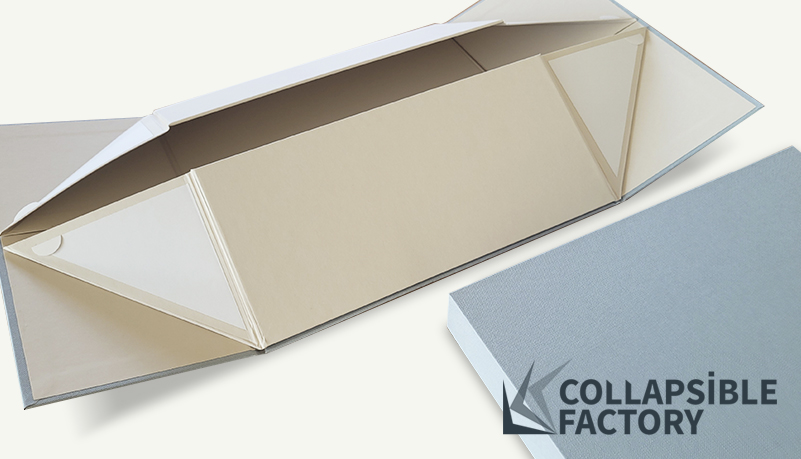

The collapsible rigid gift box is an excellent choice for packaging. It has the same advantages as rigid boxes (durability, quality, appearance), But can also be transported and stored flat.

PRODUCTION OF COLLAPSIBLE RIGID GIFT BOX

From design to delivery, we offer a full sevice and wide range manufaturing experiences. Our fully automated production line with tailor-made robotized assembly machines provide effecient workflow and consistently high quality products.

WE DESIGN

Our team of more than 10 skilled designers will provide professional assistance to implement your ideas and develop the most efficient product. From the finished/agreed design we can create a product sample for testing.

WE PRODUCE

Keskeny Printing House is the only company in Europe producing collapsible rigid gift boxes using unique and fully automated technology.

WE DELIVER

After the products have been manufactured, we can organise delivery anywhere in the world.

PRODUCT PORTFOLIO

A choice to suit all needs. In addition to the standard box options, we also design according to individual ideas. Choose from our collection.

ADVANTAGES OF COLLAPSIBLE

RIGID BOX FACTORY

We present Europe’s most modern collapsible rigid box factory with the following advantages which make our service worth choosing.

Fully automated production

Thanks to the fully automated robotic assembly line, production lead time shortens significantly and ensures optimal deadline for your boxes.

Made in Europe

The location of the factory is suitable for fast administration, continuous communication and process control.

10,000 boxes/day

Collapsible rigid gift box production with outstanding production capacity in Europe.

Various design possibilities

For the production of boxes, in addition to a wide range of sizes, we offer a large variety of raw materials and surface finishing solutions.

Quality production

The fully automated production technology guarantees consistently high quality throughout the production process.

Flexible delivery conditions

Our factory is located in the heart of Europe, ensuring reliable, fast and flexible delivery solutions.

The perfect solution

for cost-efficient transport and space-saving storage.

Attention-grabbing

quality product that appeals to customers with its elegance.

Exclusive appearance

through the use of unique surface treatments and materials.

Protection

Maximum protection of the products thanks to the thickness and strong hold of the core material.

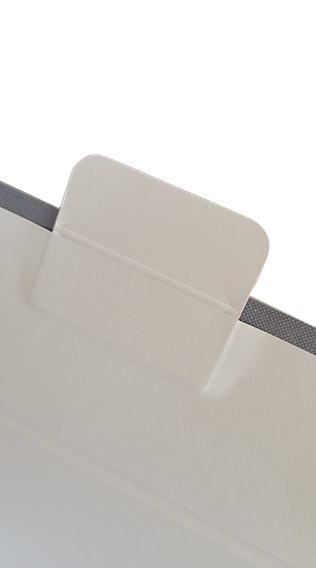

Customization

To the customer

Flexible production schedule

adapted to customer needs.

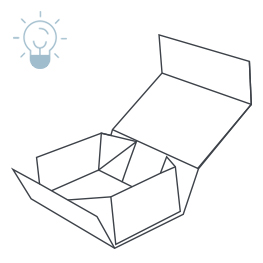

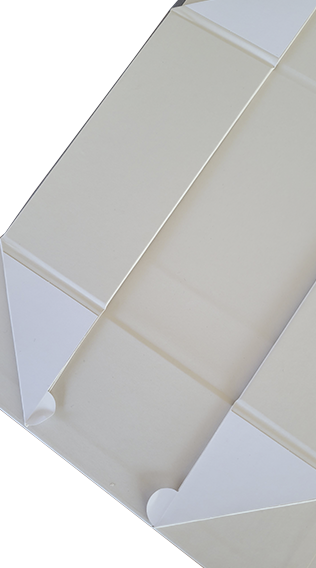

COLLAPSIBLE BOX

An excellent packaging choice not just for luxury products. Due to the variety of box constructions and the large selection of available materials, the number of possibilities also increases in terms of use.

Surface finishing options

A wide range of surface treatments are available. Printing, foiling, embossing, hot- and cold-foil stamping and varnishing with different results can be applied to the boxes depending on the wrapping material. The use of creative papers combined with surface treatments gives elegant, exclusive and unique products.

Material and surface treatment options

Standard materials:

- 2 mm greyboard for box structure

- 110 g – 130 g wrapping paper for box covering

Standard surface treatments:

- Unprinted wrapping paper with hot foil stamping

- 4 color printed wrapping paper with matte lamination

Beside the standard options we can offer a wide range of creative papers and surface treatment possibilities tailored to your unique requirements.

FREQUENTLY ASKED QUESTIONS

Do you have questions? We’ll give you the answers. If you cannot find the information you are looking for, contact us at hello@collapsiblefactory.com

How can I request a quote?

For a quote, please contact our colleagues at the email address above. If you have any questions during the process, please contact us for a call back.

What is the minimum quantity I can order?

For optimum production, the minimum order quantity starts at 500 pieces depending on the box type, but we can also accept smaller quantities on the basis of an individual quote.

Can I get a sample of the box before production?

Of course, we will produce a construction sample with the parameters and materials specified in the quotation for approval.

What is the process of ordering?

Contact our colleagues at hello@collapsiblefactory.com and request a quote. If our offer is acceptable, you can order the desired boxes by e-mail. Our staff will assist you throughout the production process.

FACTS AND FIGURES

Need more information? Here you will find the most important facts about production.

Materials

We provide a wide range of materials, including creative and environmentally certified papers as well from stock.

Constructions

We offer eight different box types from our standard product range. See OUR PORTFOLIO.

Design related info

We can also design constructions in individual sizes and implement new concepts and projects, with advice on materials and surface treatments.

Machines and processes

We manufacture using Heidelberg printing machines, Bobst die-cut machines, Kolbus and Emmeci rigid assembly machines. Fully automated processes help to maintain efficiency and guarantee high quality.

Quality assurance

Our production process is managed according to ISO 9001 and ISO 14001 standards which is continuously monitored by high skilled quality controllers. We are FSC, PEFC and HACCP certified.

Production capacity

Thanks to the automated production, we can produce up to 10 000 boxes per day.

Deadlines

Depending on the raw material, construction and quantity, we can produce the ordered quantity in 3-4 weeks.

Delivery options

We can arrange delivery of the finished product on request, but we can work with our partners’ transport companies as well.

Location

Our factory is located in the heart of Europe, in Budapest, which is ideal for customer relations, order preparation, production and logistics.

MEET THE TEAM

We offer our partners support and professional assistance with quotations, orders and production.

Árpád KESKENY

Co-Founder and CEO

Ágnes FORMESZTER

Head of Regional Sales

János CSIERNYIK

Head of Regional Sales

Ivett BODNÁR

Business Development Manager

Keskeny Printing & Packaging

The biggest milestones of our printing house

Base area: 25000 ㎡

5.5 mio box / year

41 mio € revenue

453 employees